This instruction show you guide on how to perform engine coolant drain and flush for New Holland T9 series tractor.

WARNING

Burn hazard!

Hot coolant can spray and scald if you remove the radiator or deaeration tank cap while the system is hot. To remove the cap: allow the system to cool, turn the cap to the first notch, and wait for all pressure to release. Remove the cap only after all pressure has released.

Failure to comply could result in death or serious injury.

Related Contents:

2025 CNH EST 9.12 9.10 New Holland Diagnostic Software Free Download

Procedures:

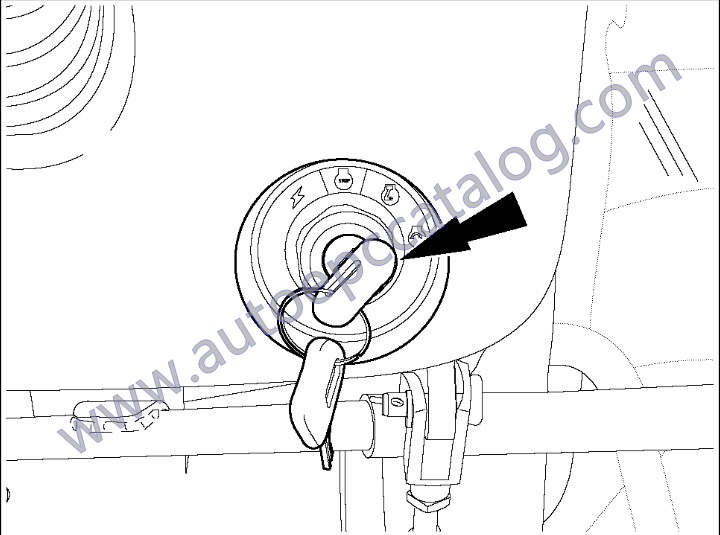

1 Park the tractor on a level surface and turn the engine off. Remove the key from the switch.

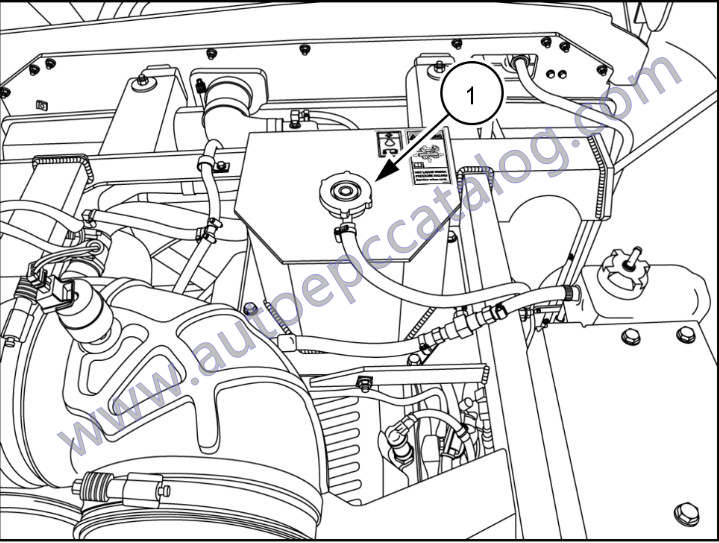

2 After the engine has cooled down, loosen the deaeration tank cap (1) to the first notch.

NOTICE: The pressure cap on a pressure cooling system has a control valve that operates as a safety relief valve to keep the pressure within the system operating range. Operating the engine without a pressure cap can cause damage.

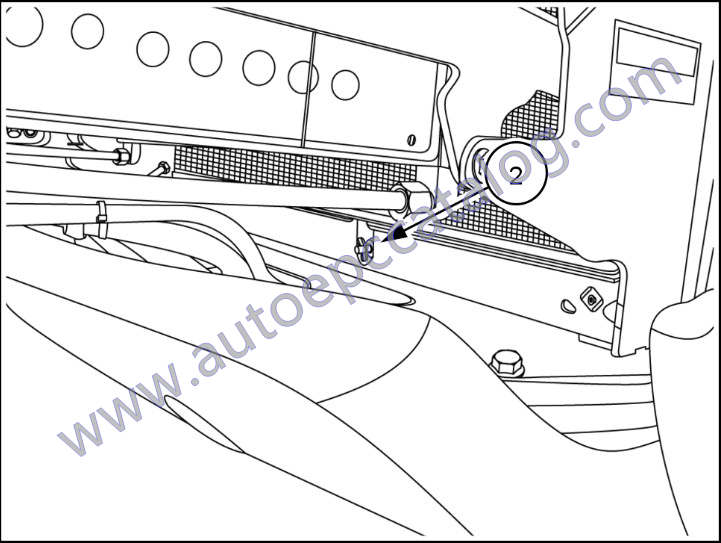

3 Open the radiator drain (2) and collect the coolant in a container.

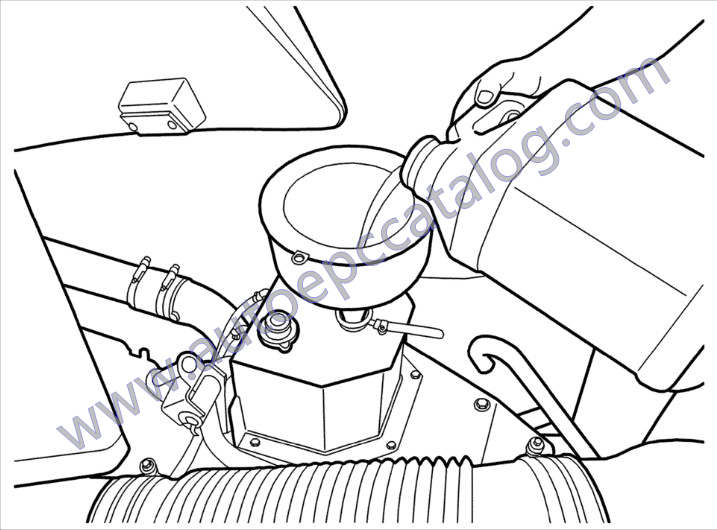

4 Remove the deaeration tank cap (1) and install a good commercial grade radiator cleaner and fill the system with clean water.

NOTICE:Follow the instructions given on the product label for use. Be sure the cleaner is compatible with the aluminum radiator core.

5 Remove the radiator cleaner solution and flush the system with clean water as directed on the product label.

6 Inspect all cooling system hoses and fittings including the heater hoses for condition and leaks.

7 Fill the cooling system with the 50/50 solution of AMBRA ACTIFULL?OT EXTENDED LIFE COOLANT/AKCELA ACTIFULL?OT EXTENDED LIFE COOLANT and distilled water to the fill neck of the deaeration tank.

8 Start the tractor engine and run at low idle for one to two minutes. Stop the engine and check the coolant level in the deaeration tank. If necessary, fill the tank to the fill neck and install the pressure cap.

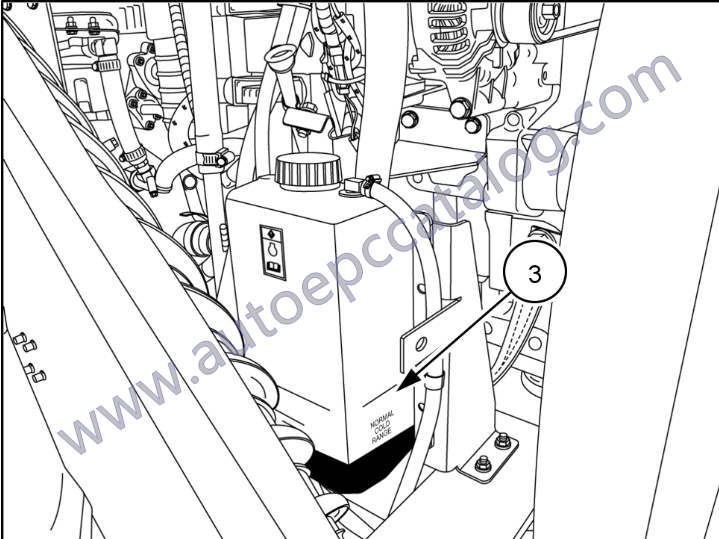

9 Fill the coolant recovery reservoir (3) with coolant solution to the full line and install the cap.

10 Start the engine and run the engine at 1200 – 1500 RPM to increase the coolant temperature to the normal operating range.

11 Stop the engine and allow the coolant to cool. Inspect the cooling system for leaks.

12 After the engine is cold, check the coolant level at the recovery reservoir only. Do not remove the deaeration tank cap. If necessary, add coolant solution to the recovery reservoir.