This instruction show you guide on how to solve Liebherr LH40 excavator machine rocking under certain working condition.

Preparations:

2020 2018 Liebherr Lidos Offline EPC+Service Manual Full Free Download

Reason:

When operating the boom and stick functions simultaneously, machines of type LH 40 to LH 80 with emission level IV(tier 4f) may tend to rock.

Cause:

The cause of the rocking is an overly aggressive control pressure signal.

Measures on machines in production:

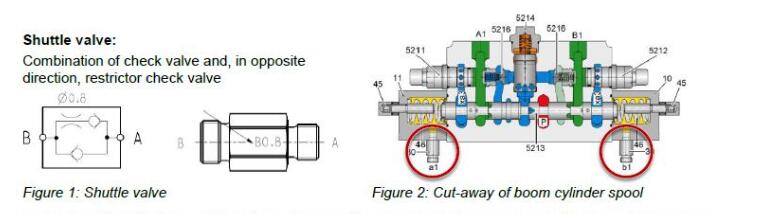

After the first feedback from the market,0.8 mm shuttle valves were installed on the servo caps of the boom cylinder spool as well as on the servo caps of the stick cylinder spool (on both control blocks). The shuttle valves dampen the control pressure signal.

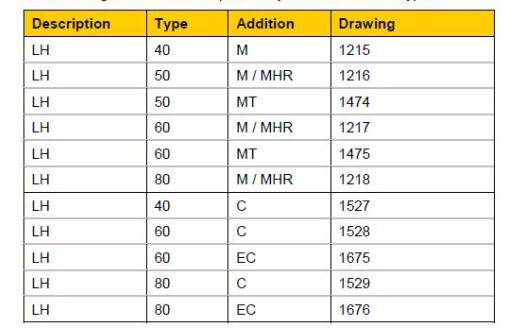

Starting from the following serial numbers,new machines by standard are equipped with these shutle valves:

H40M Type 1215 from serial number 104894,exception:105232

H50M/MHR Type 1216 from serial number 104896

H50MT Type 1474 from serial number 105240

H60M/MHR Type 1217 from serial number 105241

H60MT Type 1475 from serial number 106717

H80M/MHR Type 1218 from serial number 105244

H40C Type 1527 from serial number 105231

H60C Type 1528 from serial number 106512

H80C Type 1529 from serial number 105261

Field measures:

If already delivered machines tend to rock under the mentioned working conditions, then the shuttle valves item code 1169 9237 should be retrofitted.

The shuttle valves only need to be retrofitted in case of the behavior described above. Active conversion is not necessary.

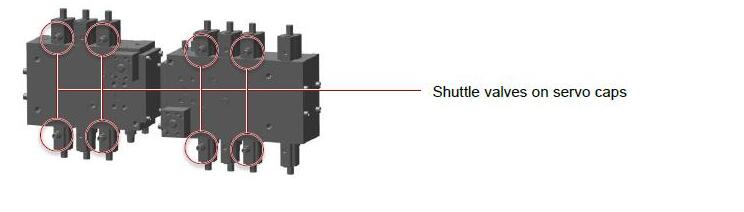

Per machine,8 shuttle valves are needed:

on control block/boom block:

-one valve each on the servo caps of the boom cylinder spool(connection side A and B)

-one valve each on the servo caps of the stick cylinder spool(connection side A and B)

on control block/stick block:

-one valve each on the servo caps of the boom cylinder spool (connection side A and B)-one valve each on the servo caps of the stick cylinder spool(connection side A and B)

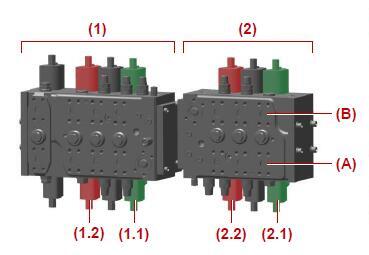

Control block,front side(example LH 40 M):

(1) Control block/boom block

(1.1) Boom cylinder spool

(1.2) Stick cylinder spool

(2) Control block/stick block

(2.1) Boom cylinder spool

(2.2) Stick cylinder spool

(B) Connection side B

(A) Connection side A

Control block,rear side(example LH 40 M):

Affected machines:

The following table lists all the potentially affected machine types.

A detailed list of all potentially affected machines with serial numbers can be found in the appendix and in Liebherr Warranty Manager(LiWM).

Settlement:

If already delivered machines tend to rock under the mentioned working conditions, then the shuttle valves should be retrofitted during the next service appointment. Active conversion is not necessary, but only when a machine tends to rock!!

The costs incurred by you will be reimbursed as follows:

Material: per machine 8x shuttle valves, item code 1169 9237

Work time:

2 hour

Travel expenses:

If the work cannot be carried out during a service, we will reimburse the travel time and mileage once per machine/job site.

Please submit the costs incurred using a warranty claim referring to the number LHB-080-05-79/18.

To ensure trouble-free processing, no other actions must be listed on the warranty claim.

Deadline:

The replacement must be done by 30/11/2020 at the latest. If payment is required, the warranty claim must be received by us no later than 30 days after the repair has been completed.