This instruction show you guide on how to perform activate test and supply pump difference learning for Kubota V3800 diesel engine.

Related Contents:

Takeuchi Excavator Workshop EPC+Service Manual 2018 PDF Files

2022 Kubota Takeuchi Diagmaster v22.08.01 v4.1.2 Software Free Download

Kubota EPC Spare Parts Catalogue 2021.06 Download

(Operating conditions → Specified Tool conditions)

1.The conditions below are required for 1. Injector non-injection instruction and 4. Supply pump difference learning:

Machine is stopped (KWPSPD = 0)

Neutral switch is ON (XNEU = 1 or ON)

1.Injector non-injection instruction

Stop the injection for each cylinder injector in accordance with the requests from the tool.

Engine vibration and noise are increased when the injection for the corresponding cylinder is stopped. The same results must be attained from all the cylinders.

NOTE:

Do not judge with the corresponding cylinder only: also compare with the symptoms in the other cylinders.

2.EGR actuation test

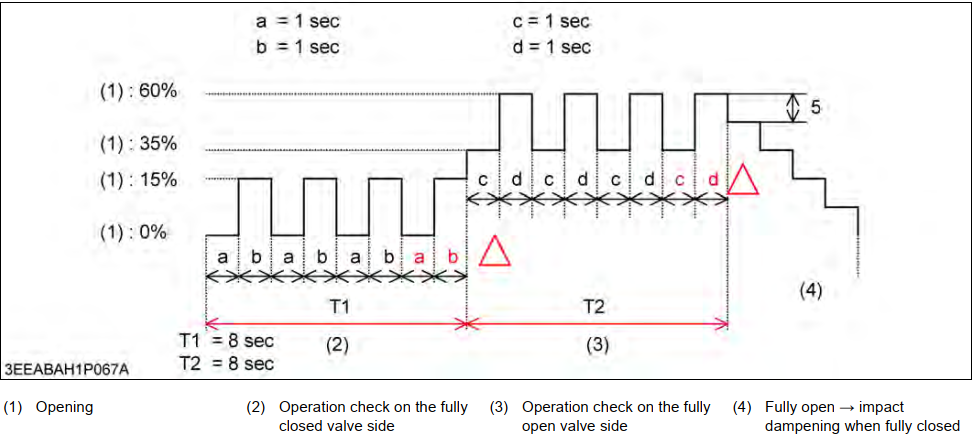

Operate as shown in the diagram below and in accordance with the requests from the tool.

Low side: When target EGR valve openings of 0% and 15% are given alternately, there must not be disparity in the actual EGR valve opening. High side: When target EGR valve openings of 35% and 60% are given alternately, there must not be disparity in the actual EGR valve opening.

NOTE:

In some cases the actual opening may be different from the target opening. The reason for this is because the learning value is always reflected for 0 lift, after being used for a long time 0 points are shifted. As such, the factory spec. is a relative evaluation and not an absolute evaluation.

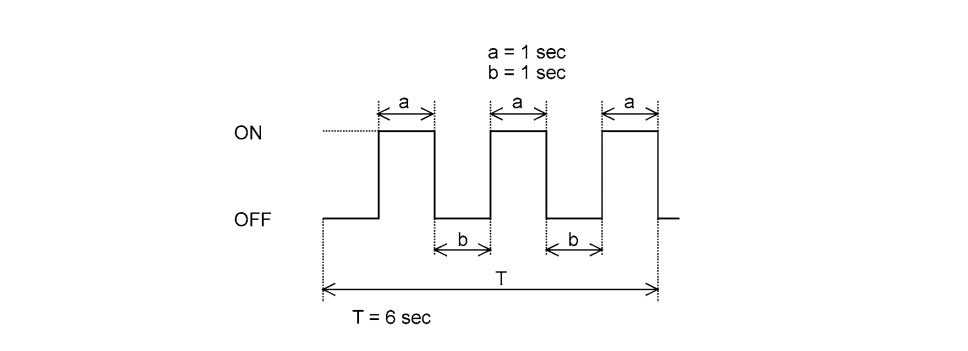

3.Air heater relay actuation test

Operate as shown in the diagram below and in accordance with the requests from the tool.

Supply pump difference learning (clear the learning value)

IMPORTANT

• Must be performed after replacing the supply pump or ECU.

• Clear the learning completion flag in accordance with the requests from the tool. (Initialize)

A difference learning completion message comes from the tool. In addition, when the “Pump difference learning status” is checked with the monitor function, the status is 2 or 3.

NOTE

When the diagnosis related pressure is detected, or when the actual rail pressure can not follow the target pressure properly, perform pump difference learning and see what happens. (As there are some cases that can not complete the relearning (status 2) from status 3.)

This major symptom is extreme air in fuel line or filter clogged etc., and it normally occurred when operating with the extreme vacuum pressure. Perform pump difference learning particularly when there placement of the filter (too much dirt) has not performed or the engine stalls by air in fuel line etc.

(The conditions of pump difference learning)

• Condition of the pump difference learning is ; After the engine has warmed up (after the thermostat is opened) and the machine is stopped + the neutral switch is ON (neutral status) + the engine is idling (accelerator open position 0 %).