This instruction show you guide on how to replace wheel drive and motor for JLG X14J lift.

Preparations:

JLG Technical Library Service Repair+Parts Manual 2020 Download

Procedures:

1.Stabilize the machine on level ground.

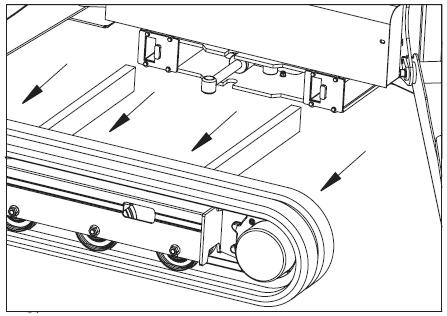

2.Fully extend the undercarriage.

3.Remove the tracks (see paragraph 3.1).

4.Remove the key ignition, and a tag with warning do not start the machine.

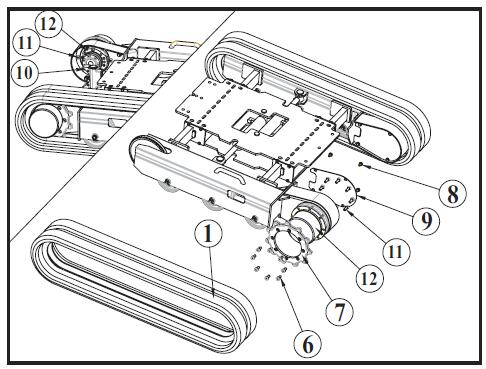

5.Remove screws 6.

6.Remove the sprocket 7.

7.To ensure a lifting system for the gearmotor 12 (30kg).

8.Disconnect and tag the hydraulic hoses from the gearmotor.

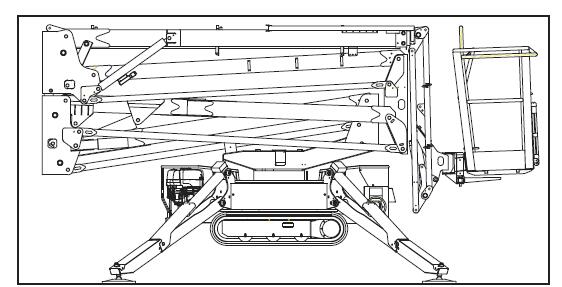

9.Remove the valve 10 to access all the screws 11 (on single speed versions only).

10.Remove the screws 11.

11.Remove the gear motor 12.

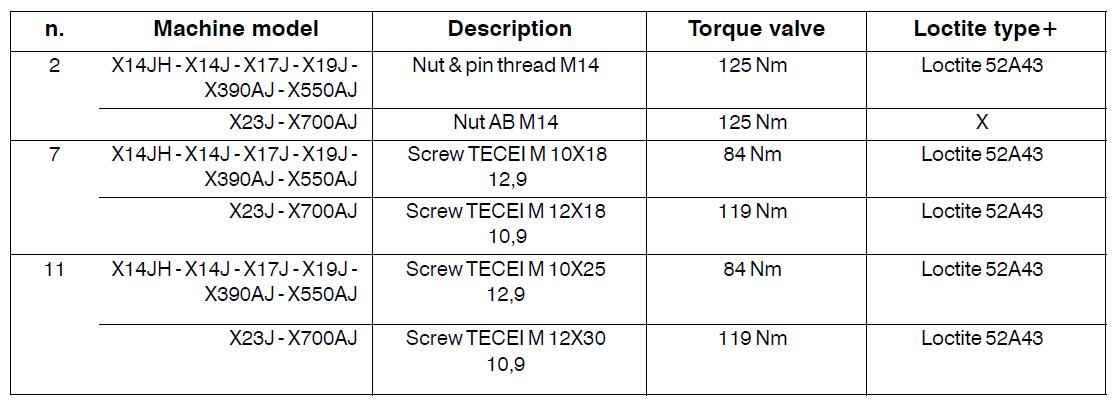

Final drive torque valves

12.Stabilize the machine on level surface.

13.Extend the undercarriage.

14.Engine and key off.

15.Remove the key ignition, and a tag with warning do not start the machine.

16.Open the hydraulic cap, and operate the function undercarriage extend/retract to discharge any residual pressure in the system.

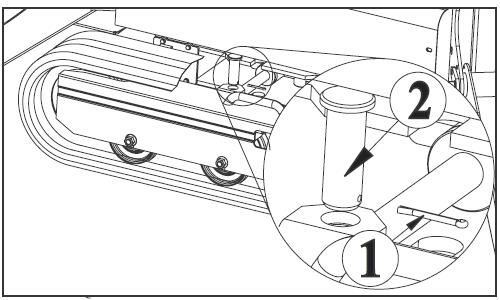

17Remove the cotter pin 1.

18Remove the pin 2.

19.Using a suitable lifting (minimum 200kg) to remove the track frame.

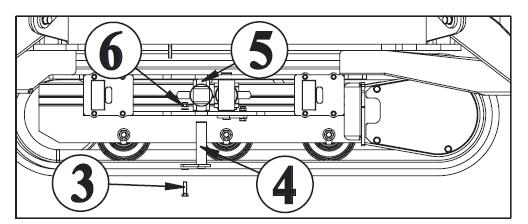

20.Remove screw and nut 3-6.

21.Remove the pin 4.

22.Disconnect, tag and plug the hydraulic hoses from the cylinder extension.

Remove the cylinder.

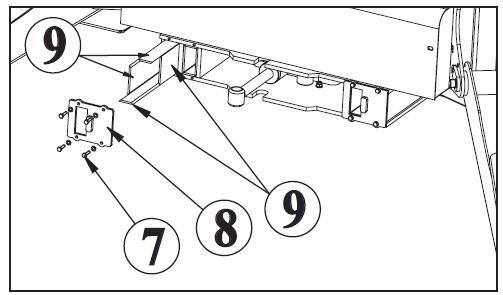

NOTE: Before to install the undercarriage frame inspect the slide guides 9.

a.Unscrew the screws 7.

b.Remove the stop slide guides 8.

c.Remove the slide guides 9.

d.Check the thickness of slide guides, if less than 3.5 mm, damage, with deep scratches or with deformation, replace its. Otherwise clean them and install by adding Grease GR MU EP1 before to install the track guides.

e.Use medium strength Loctite (Loctite 52A43) on screws 7 and tightening torque of 10 Nm.