This instruction show you guide on how to remove and install speed sensor for Meritor Wabco Easy-Stop Trailer.

Preparations:

Meritor Wabco Toolbox 13+ECAS CAN2 V3.00 Download & Installation

Meritor Wabco Toolbox Diagnostic Software Download

How to Remove a Sensor

1.Follow the vehicle manufacturer’s instructions to back off the slack adjuster and remove the tire, wheel and drum.

2.Hold the sensor, not the cable, and use a twisting motion to pull the sensor out of its mounting block.

3.Remove the spring clip from the mounting block.

4.Remove any fasteners that hold the sensor cable to other components.

5.Disconnect the sensor cable from the extension cable.

How to Install a Sensor

Sensor locations vary according to suspension types. Typically, a spring suspension has sensors on the forward axle, and an air suspension has sensors on the rear axle.

1.Apply a mineral oil-based grease that contains molydisulfide to the sensor spring clip and to the body of the sensor. The grease must be anti-corrosive and contain adhesive properties that will continuously endure temperatures from –40° to 300°F (–40° to 150°C).

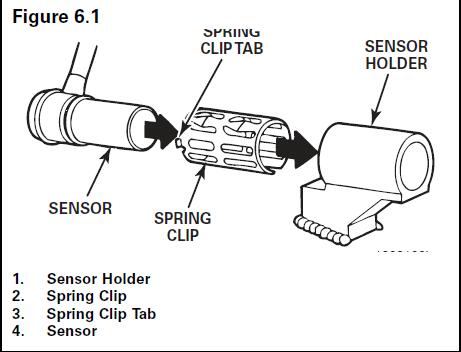

2.Push the spring clip into the sensor holder from the inboard side, until the spring clip tabs are against the sensor holder. Push the sensor into the spring clip as far as possible.

3.Route the sensor cable toward the brake chamber, over the brake spider, and behind the axle. Secure the cable to the axle between the brake spider and the suspension brackets.

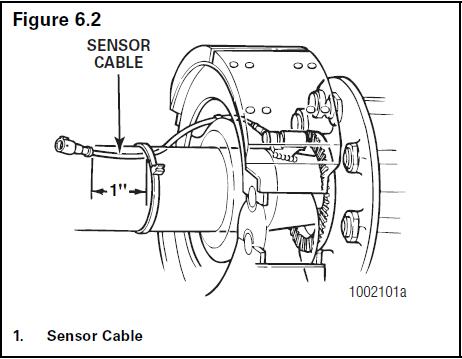

Continue to route the sensor cable behind the spring seats. Secure the cable to the axle one inch from the molded sensor plug. Figure 6.2.

4.Install the wheel hub carefully, so that the tooth wheel pushes against the sensor as you adjust the wheel bearings. After installation there should be no gap between the sensor and the tooth wheel. During normal operation a gap of 0.040-inch is allowable.

5.Sensor Output Voltage Test: Use a volt/ohm meter to check the AC output voltage of the sensors while rotating the wheel at approximately one-half revolution per second.Minimum output must be greater than 0.2 volts AC. If minimum output is less than 0.2 volts AC, push the sensor toward the tooth wheel. Recheck the sensor output.