Here is an instruction show you guide on how to adjust the sensors on the rack collision protection system for Linde R1120-1 forklift truck.

Preparations:

2023 Linde Service Guide LSG 5.2.2 U0278 and 5.1.2 Free Download

Description

Linde MH has been informed that the light point spacing between the sensors of the rack collision protection system is too large for some loads.

Course of action

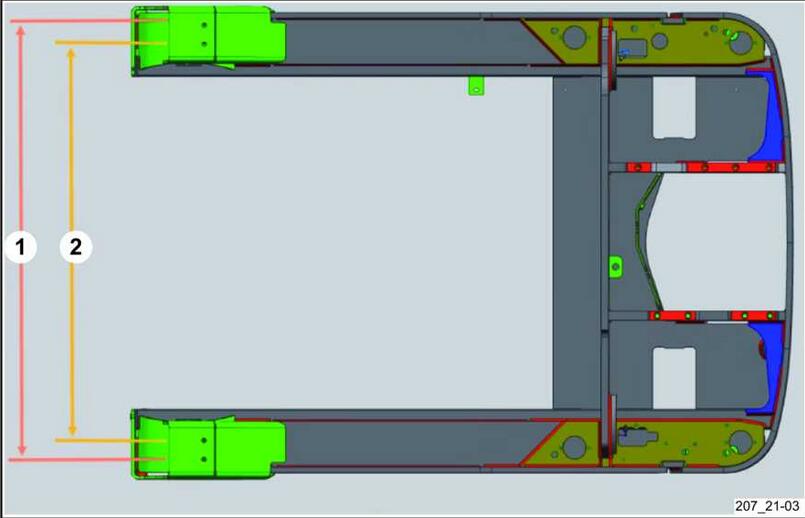

1 Standard (sensor in the outer position) = 1216 mm

2 Narrow loads (sensor in the inner position) = 1076 mm

For smaller loads, the sensors of the rack collision protection system can be rotated by 180°. This reduces the light point spacing.

For smaller loads, the sensors of the rack collision protection system can be rotated by 180°. This reduces the light point spacing.

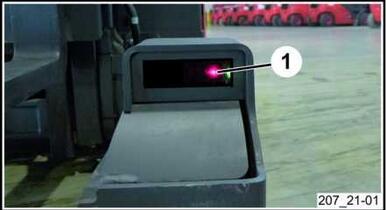

Standard

Sensor in the outer position (1)

Light point spacing: 1216 mm

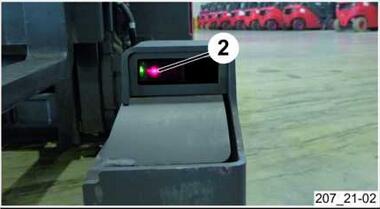

Narrow loads

Sensor in the inner position (2)

Light point spacing: 1076 mm

Comment

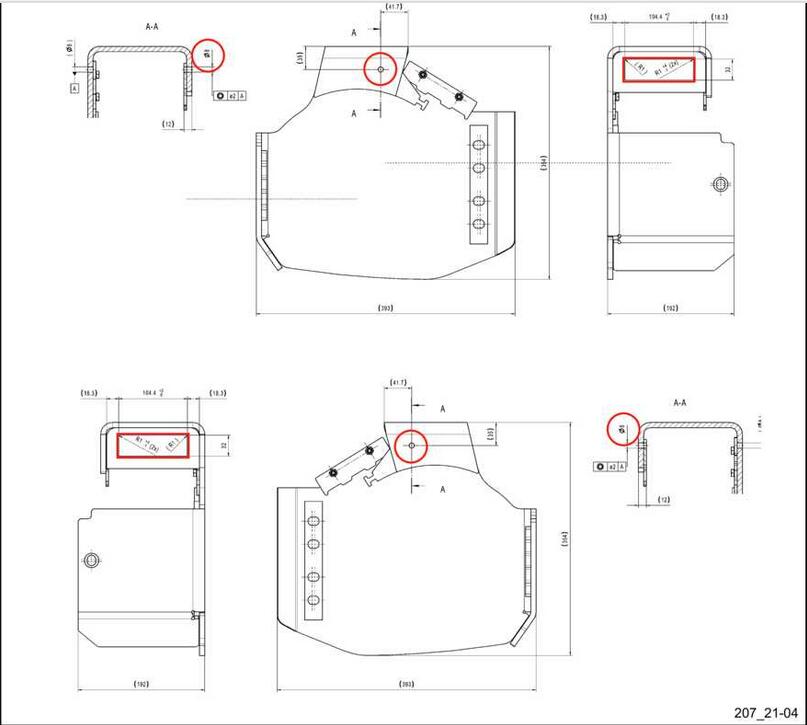

If the customer’s existing trucks have already been fitted with a rack collision protection system with a narrow sensor cut-out, the sensor supports can be modified with the following rework:

R14 – R16

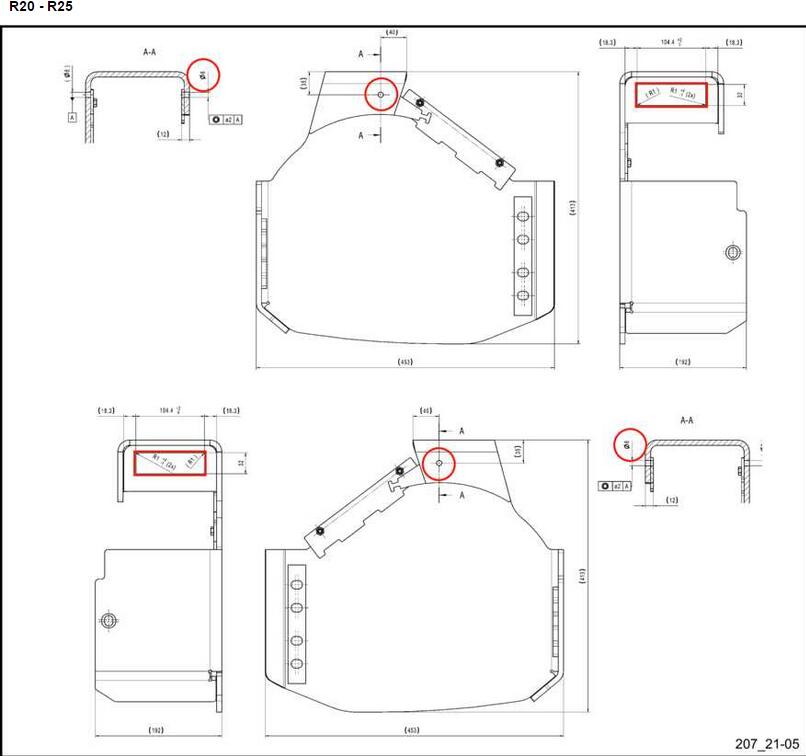

R20 – R25

Comment

This Service Information describes a technical change and a problem that may arise in the field. It is not an instruction for a general modification or repair. The information contained within this Service Information does not provide the basis for any warranty claim.

More service information,please refer to:Linde Forklift Truck Repair